Safety capacitor JY103M Y2

Details

|

|

|

|

|

|

|

|

|

|

|

Approval Standard And Recognized NO.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Safety Standard

|

Standard NO.

|

Recognized NO.

|

Approved Monogram

|

|

UL ( USA )

|

|

UL60384-14

|

E187963

|

|

|

VDE ( Germany )

|

EN 60384-14:2005 IEC 60384-14 (ed.3):05

|

123326

|

|

|

SEMKO ( Sweden )

|

EN 60384-14:2005

|

|

|

908155

|

|

|

SEV ( Switzerland )

|

IEC 60384-14 (ed.3):05

|

|

|

09.0785

|

|

|

FIMKO ( Finland )

|

EN 60384-14:2005

|

|

|

FI 24995 A1

|

|

|

NEMKO ( Norway )

|

EN 60384-14:2005

|

|

|

P09211069

|

|

|

DEMKO ( Denmark )

|

EN 60384-14:2005

|

|

|

147932-03

|

|

|

VDE CB

|

|

|

IEC 60384-14:2005

|

|

FI 5709 A1

|

|

CB

|

|

|

|

|

|

|

|

|

|

|

|

Specifications:

|

|

|

|

|

|

|

|

|

Operating Temp. Rang

|

-25℃ to +85℃

|

|

|

|

Approved Monogram

|

UL, SEMKO, SEV, FIMKO, NEMKO, DEMKO, VDE

|

X1 Y2

|

|

|

|

|

400 VAC 300VAC

|

|

|

|

|

Dielectric

|

Rated Voltage

|

|

Test Voltage

|

|

|

|

Withstanding Voltage

|

300 VAC

|

|

|

2600 VAC for 1 min.

|

|

Dissipation Factor(D.F)

|

Y5P、Y5U

|

TANδ≦2.5%, measured at 1KHz±10%, 1.0 - 5.0 Vrms, 25℃

|

|

Y5V

|

TANδ≦5.0%, measured at 1KHz±10%, 1.0 - 5.0 Vrms, 25℃

|

|

|

Capacitance( C )

|

Range

|

10pF to10000pF.measured at 1KHz±10%, 1.0 - 5.0 Vrms, 25℃

|

|

|

|

±10%

|

|

Y5P

|

|

|

|

|

|

±10%、±20%

|

Y5U

|

|

|

|

|

Tolerance

|

±20%

|

|

Y5V

|

|

|

|

|

Insulation Resistance( I R )

|

10,000 MΩ min, 100 VDC

|

|

|

|

|

|

Temperature Characteristics

|

Type Code

|

Cap. Change

|

Temp. Range

|

|

|

|

Y5P

|

±10%, max.

|

-25℃ to +85℃

|

|

|

Y5U

|

+22%, -56% max.

|

-25℃ to +85℃

|

|

|

Y5V

|

+30%, -80% max.

|

-25℃ to +85℃

|

|

|

The reference temperature: 25 ℃

|

|

|

|

|

|

Y2 SERIES

|

|

|

|

|

|

|

|

|

INTRODUCTION

|

|

|

|

|

|

|

|

These Ceramic Disc Capacitors are specifically designed for AC applications and meet the

|

|

|

|

safety requirements of various safety standards agencies.These capacitors are ideal for across

|

|

|

the line and line by-pass applications

|

|

|

|

|

|

|

FEATURES:

|

|

|

|

|

|

|

|

⊙Ideal for across the line applictions

|

|

|

|

|

|

|

⊙Compact size

|

|

|

|

|

|

|

|

⊙Cost effective product

|

|

|

|

|

|

|

|

⊙Safety standards recognized for AC applications

|

|

|

|

|

|

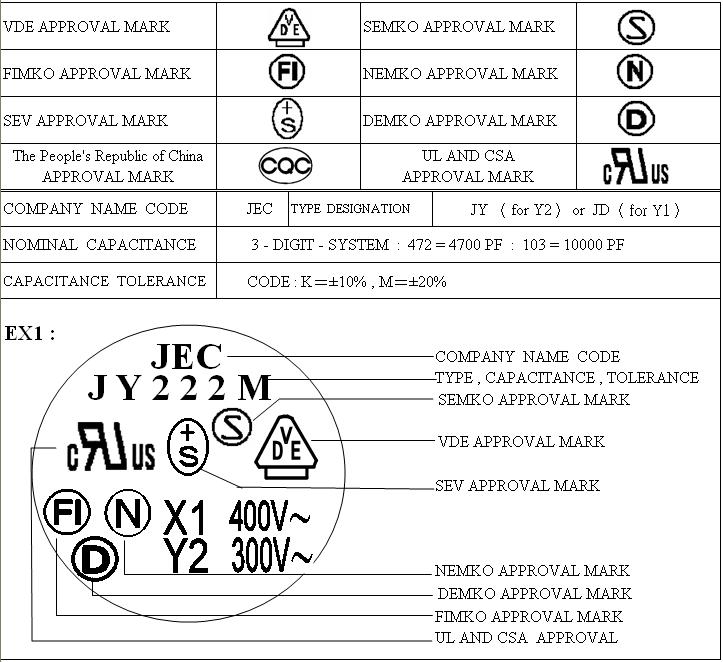

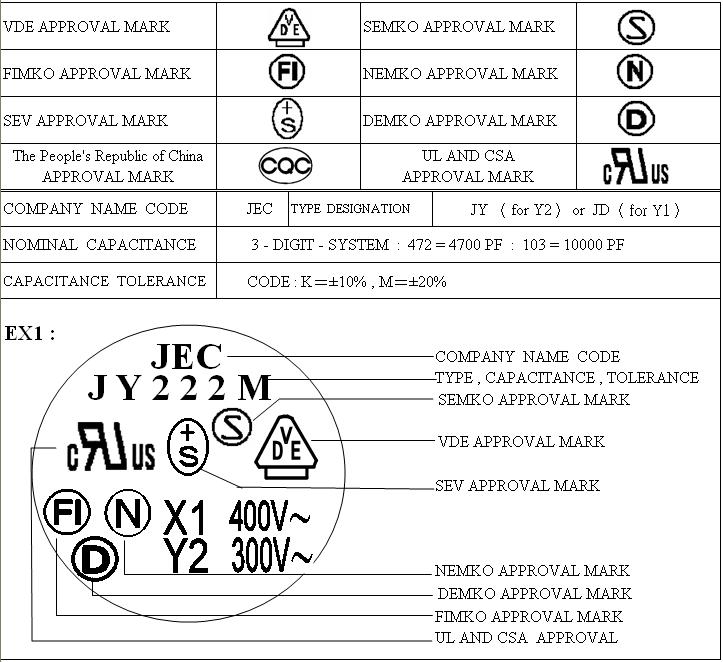

Part Number Configuration :

|

|

|

|

|

|

|

|

JY 102 K Y5P Y2

|

|

(1) AC capacitors, safety

|

(4) Type code: Y5P,Y5U,Y5V

|

|

|

(1) (2) (3) (4) (5)

|

|

(2) Rated capacitance

|

(5) Class Y2

|

|

|

|

|

|

|

(3) Tolerance on rated capacitance

|

|

|

|

|

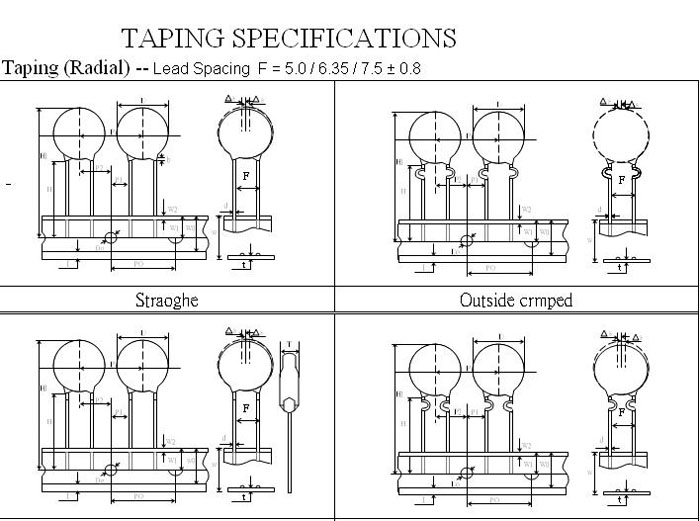

PART NUMBER

|

|

|

|

|

DIMENSION(mm)

|

|

|

|

|

|

|

D

|

F

|

T

|

|

JY10KY5P Y2

|

|

10PF

|

|

6.5Φ

|

7.5±0.8

|

<5.0

|

|

to

|

|

to

|

|

6.5Φ

|

7.5±0.8

|

<5.0

|

|

JY82KY5P Y2

|

|

82PF

|

|

6.5Φ

|

7.5±0.8

|

<5.0

|

|

JY101KY5P Y2

|

|

100PF

|

|

6.5Φ

|

7.5±0.8

|

<5.0

|

|

JY151KY5P Y2

|

±10%

|

150PF

|

K

|

6.5Φ

|

7.5±0.8

|

<5.0

|

|

JY221KY5P Y2

|

(Y5P)

|

220PF

|

±10%

|

6.5Φ

|

7.5±0.8

|

<5.0

|

|

JY271KY5P Y2

|

|

270PF

|

|

6.5Φ

|

7.5±0.8

|

<5.0

|

|

JY331KY5P Y2

|

|

|

330PF

|

|

6.5Φ

|

7.5±0.8

|

<5.0

|

|

JY471KY5P Y2

|

|

|

470PF

|

|

7.5Φ

|

7.5±0.8

|

<5.0

|

|

JY561KY5P Y2

|

|

|

560PF

|

|

7.5Φ

|

7.5±0.8

|

<5.0

|

|

JY681KY5P Y2

|

|

|

680PF

|

|

7.5Φ

|

7.5±0.8

|

<5.0

|

|

JY102KY5P Y2

|

|

|

1000PF

|

|

8.5Φ

|

7.5±0.8

|

<5.0

|

|

JY471KY5U Y2

|

|

470PF

|

K±10%

|

6.5Φ

|

7.5±0.8

|

<5.0

|

|

JY561KY5U Y2

|

|

560PF

|

7.5Φ

|

7.5±0.8

|

<5.0

|

|

JY681KY5U Y2

|

|

680PF

|

7.5Φ

|

7.5±0.8

|

<5.0

|

|

JY102MY5U Y2

|

+22 ~ -56%

|

1000PF

|

|

7.5Φ

|

7.5±0.8

|

<5.0

|

|

JY222MY5U Y2

|

(Y5U)

|

2200PF

|

M

|

9.5Φ

|

7.5±0.8

|

<5.0

|

|

JY332MY5U Y2

|

|

3300PF

|

11.0Φ

|

7.5±0.8

|

<5.0

|

|

JY472MY5U Y2

|

|

4700PF

|

±20%

|

13.0Φ

|

7.5±0.8

|

<5.0

|

|

JY102MY5V Y2

|

|

|

1000PF

|

|

6.5Φ

|

7.5±0.8

|

<5.0

|

|

JY152MY5V Y2

|

|

|

1500PF

|

|

6.5Φ

|

7.5±0.8

|

<5.0

|

|

JY222MY5V Y2

|

|

|

2200PF

|

|

7.0Φ

|

7.5±0.8

|

<5.0

|

|

JY332MY5V Y2

|

|

+30 ~ -80%

|

3300PF

|

M

|

9.0Φ

|

7.5±0.8

|

<5.0

|

|

JY392MY5V Y2

|

|

(Y5V)

|

3900PF

|

±20%

|

10.5Φ

|

7.5±0.8

|

<5.0

|

|

JY472MY5V Y2

|

|

|

4700PF

|

|

9.5Φ

|

7.5±0.8

|

<5.0

|

|

JY562MY5V Y2

|

|

|

5600PF

|

|

11.5Φ

|

7.5±0.8

|

<5.0

|

|

JY682MY5V Y2

|

|

|

6800PF

|

|

11.5Φ

|

7.5±0.8

|

<5.0

|

|

JY822MY5V Y2

|

|

|

8200PF

|

|

12.5Φ

|

7.5±0.8

|

<5.0

|

|

JY103MY5V Y2

|

|

|

10000PF

|

|

14.0Φ

|

9.5±0.8

|

<5.0

|

|

|

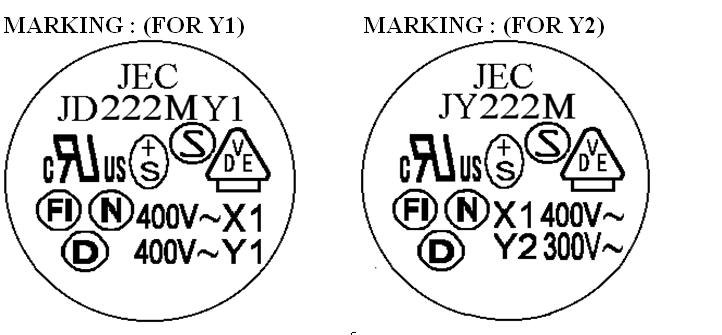

Dimensions and Tolerance

|

|

TYPE:FS

|

|

|

|

|

B= 3.0 mm max for FS

|

|

|

X1 400VAC Y2 300VAC

|

|

|

|

|

d=0.55 mm ±0.05 mm

|

|

|

|

|

|

|

F=6.35 or 7.5 or 9.5 ±0.8 mm

|

|

|

|

|

|

|

L=3 ~ 33 mm.

|

|

|

|

|

|

|

|

◎ According as customer's request and size.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Approval Standard And Recognized NO.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Safety Standard

|

Standard NO.

|

Recognized NO.

|

Approved Monogram

|

|

UL ( USA )

|

|

UL60384-14

|

E187963

|

|

|

VDE ( Germany )

|

EN 60384-14:2005 IEC 60384-14 (ed.3):05

|

173027

|

|

SEMKO ( Sweden )

|

EN 60384-14:2005

|

|

|

908154

|

|

SEV ( Switzerland )

|

IEC 60384-14 (ed.3):05

|

|

|

09.0784

|

|

FIMKO ( Finland )

|

EN 60384-14:2005

|

|

|

FI 24994 A1

|

|

NEMKO ( Norway )

|

EN 60384-14:2005

|

|

|

P09211070

|

|

DEMKO ( Denmark )

|

EN 60384-14:2005

|

|

|

147936-03

|

|

VDE CB

|

|

|

IEC 60384-14:2005

|

|

FI 5708 A1

|

CB

|

|

|

|

|

|

|

|

|

|

|

|

Specifications:

|

|

|

|

|

|

|

|

|

Operating Temp. Rang

|

-25℃ to +85℃

|

|

|

|

Approved Monogram

|

UL, SEMKO, SEV, FIMKO, NEMKO, DEMKO, VDE

|

X1 Y1

|

|

|

|

|

400 VAC 400VAC

|

|

|

|

|

Dielectric

|

Rated Voltage

|

|

Test Voltage

|

|

|

|

Withstanding Voltage

|

400 VAC

|

|

|

4000 VAC for 1 min.

|

|

Dissipation Factor(D.F)

|

Y5P、Y5U

|

TANδ≦2.5%, measured at 1KHz±10%, 1.0 - 5.0 Vrms, 25℃

|

|

Y5V

|

TANδ≦5.0%, measured at 1KHz±10%, 1.0 - 5.0 Vrms, 25℃

|

|

|

Capacitance( C )

|

Range

|

10pF to 4700pF.measured at 1KHz±10%, 1.0 - 5.0 Vrms, 25℃

|

|

|

|

±10%

|

|

Y5P

|

|

|

|

|

|

±10%、±20%

|

Y5U

|

|

|

|

|

Tolerance

|

±20%

|

|

Y5V

|

|

|

|

|

Insulation Resistance( I R )

|

10,000 MΩ min, 100 VDC

|

|

|

|

|

|

Temperature Characteristics

|

Type Code

|

Cap. Change

|

Temp. Range

|

|

|

|

Y5P

|

±10%, max.

|

-25℃ to +85℃

|

|

|

Y5U

|

+22%, -56% max.

|

-25℃ to +85℃

|

|

|

Y5V

|

+30%, -80% max.

|

-25℃ to +85℃

|

|

|

The reference temperature: 25 ℃

|

|

|

|

|

|

Y1 SERIES

|

|

|

|

|

|

|

|

|

INTRODUCTION

|

|

|

|

|

|

|

|

These Ceramic Disc Capacitors are specifically designed for AC applications and meet the

|

|

|

|

safety requirements of various safety standards agencies.These capacitors are ideal for across

|

|

|

the line and line by-pass applications

|

|

|

|

|

|

|

FEATURES:

|

|

|

|

|

|

|

|

⊙Ideal for across the line applictions

|

|

|

|

|

|

|

⊙Compact size

|

|

|

|

|

|

|

|

⊙Cost effective product

|

|

|

|

|

|

|

|

⊙Safety standards recognized for AC applications

|

|

|

|

|

|

Part Number Configuration :

|

|

|

|

|

|

|

|

JD 102 K Y5P Y1

|

|

(1) AC capacitors, safety

|

(4) Type code: Y5P, Y5U,Y5V

|

|

(1) (2) (3) (4) (5)

|

|

(2) Rated capacitance

|

(5) Class Y1

|

|

|

|

|

|

|

(3) Tolerance on rated capacitance

|

|

|

|

|

|

|

|

|

DIMENSION(mm)

|

|

|

PART NUMBER

|

|

|

|

|

D max

|

F

|

T max

|

|

JD10KY5P Y1

|

|

10PF

|

|

7.0ф

|

9.5±0.8

|

<6.0

|

|

to

|

|

to

|

|

|

JD82KY5P Y1

|

|

82PF

|

|

|

JD101KY5P Y1

|

|

100PF

|

|

7.0ф

|

9.5±0.8

|

<6.0

|

|

JD151KY5P Y1

|

|

±10%

|

150PF

|

K

|

7.0ф

|

9.5±0.8

|

<6.0

|

|

JD221KY5P Y1

|

|

(Y5P)

|

220PF

|

±10%

|

8.0ф

|

9.5±0.8

|

<6.0

|

|

JD331KY5P Y1

|

|

|

330PF

|

|

8.0ф

|

9.5±0.8

|

<6.0

|

|

JD471KY5P Y1

|

|

|

470PF

|

|

7.0ф

|

9.5±0.8

|

<6.0

|

|

JD561KY5P Y1

|

|

|

560PF

|

|

8.5ф

|

9.5±0.8

|

<6.0

|

|

JD681KY5P Y1

|

|

|

680PF

|

|

9.5ф

|

9.5±0.8

|

<6.0

|

|

JD102KY5P Y1

|

|

|

1000PF

|

|

12.0ф

|

9.5±0.8

|

<6.0

|

|

JD102KY5UY1

|

+22 ~ -56% (Y5U)

|

1000PF

|

K±10%

|

9.0ф

|

9.5±0.8

|

<6.0

|

|

JD471MY5UY1

|

470PF

|

|

7.0ф

|

9.5±0.8

|

<6.0

|

|

JD561MY5UY1

|

560PF

|

|

8.0ф

|

9.5±0.8

|

<6.0

|

|

JD681MY5UY1

|

680PF

|

|

8.0ф

|

9.5±0.8

|

<6.0

|

|

JD102MY5UY1

|

1000PF

|

M

|

8.0ф

|

9.5±0.8

|

<6.0

|

|

JD152MY5UY1

|

1500PF

|

±20%

|

9.0ф

|

9.5±0.8

|

<6.0

|

|

JD222MY5UY1

|

2200PF

|

|

11.0ф

|

9.5±0.8

|

<6.0

|

|

JD332MY5UY1

|

3300PF

|

|

13.0ф

|

9.5±0.8

|

<6.0

|

|

JD472MY5UY1

|

4700PF

|

|

15.0ф

|

9.5±0.8

|

<6.0

|

|

JD102MY5V Y1

|

|

|

1000PF

|

|

7.0ф

|

9.5±0.8

|

<6.0

|

|

JD152MY5V Y1

|

|

|

1500PF

|

|

8.5ф

|

9.5±0.8

|

<6.0

|

|

JD222MY5V Y1

|

|

+30 ~ -80%

|

2200PF

|

M

|

9.5ф

|

9.5±0.8

|

<6.0

|

|

JD332MY5V Y1

|

|

(Y5V)

|

3300PF

|

±20%

|

11.0ф

|

9.5±0.8

|

<6.0

|

|

JD392MY5V Y1

|

|

|

3900PF

|

|

11.5ф

|

9.5±0.8

|

<6.0

|

|

JD472MY5V Y1

|

|

|

4700PF

|

|

13.0ф

|

9.5±0.8

|

<6.0

|

|

Dimensions and Tolerance

|

|

TYPE:FS

|

|

|

|

|

B= 3.0 mm max for FS

|

|

|

X1 400VAC Y1 400VAC

|

|

|

|

|

d=0.55 mm ±0.05 mm

|

|

|

|

|

|

|

F=7.5 or 9.5 or12.5±0.8 mm

|

|

|

|

|

|

|

L=3 ~ 33 mm.

|

|

|

|

|

|

|

|

◎ According as customer's request and size.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

編號

|

項 目

|

性 能

|

試 驗 方 法

|

|

|

1

|

|

外觀及

|

參考第 5 、 8 與 11 頁

|

1~1

|

生產線必須做全數外觀檢驗並分別剔除不良品。

|

|

|

|

尺寸

|

之圖表

|

1~2

|

尺寸利用微測儀或卡尺測量。

|

|

2

|

|

記號標示

|

必須乾淨及清晰。

|

2~1

|

標示需能承受異丙醇擦拭。

|

|

3

|

耐電壓

|

端子間

|

無異常。

|

3~1

|

額定電壓 : 300Vac for Y2 試驗電壓 2600 VAC,時間一分鐘 額定電壓 : 400Vac for Y1 試驗電壓 4000 VAC,時間一分鐘

|

|

|

︵I︶

|

端子、封裝間

|

無異常。

|

3~2

|

額定電壓 : 300Vac for Y2 試驗電壓 2000 VAC,時間一分鐘 額定電壓 : 400Vac for Y1 試驗電壓 4000 VAC,時間一分鐘

|

|

|

注意: 1. 批量生產時測試時間為2秒鐘 2. 耐壓測試應為緩升或零啟動 3.工作電流按容量與電壓大小限於2~5mA , 最大不可超出50mA

|

|

4

|

|

耐電壓(Ⅲ) (適用於安全性能符號A2)

|

(1)紗布須不引燃。 (2)電容器須不冒煙。

|

4~1

|

依CNS 3432,11節規定

|

|

5

|

|

耐電壓(Ⅳ) (適用於安全性能號B2)

|

(3)元件與封裝須不散飛。 (4)端子不能移動離開安裝位置3mm以上。

|

5~1

|

依CNS3432, 12節規定

|

|

6

|

|

端子間 端子、封裝間

|

10000MΩ以上。 10000MΩ以上。

|

6~1

|

測定電壓為100±50V,在一分鐘內要在規定值內。

|

|

7

|

|

靜電容量

|

必須符合要求之容許差規格內。

|

7~1 7~2 7~3

|

測定溫度25±2℃ 測定電壓:1~5Vrms以下 測定頻率:1KHz±10%

|

|

8

|

|

Q值

|

Q(CCS)值: 特性SL 1000以上。 特性YN 500以上。

|

8~1

|

與第7項同。

|

|

|

|

或散逸因數

|

散逸因數(CKS): 特性:B, E 2.5%以下。 特性:F 5.0%以下。

|

|

|

|

|

編 號

|

項 目

|

性 能

|

試 驗 方 法

|

|

9

|

靜電容量

|

溫度係數(CCS ):

|

|

9~1

|

溫度係數:(CCS)

|

|

|

|

|

溫 特性

|

SL

|

YN

|

|

PPM/℃=Ct2- Ct1

|

|

|

|

度範圍

|

|

|

|

/Ct1*(t2-t1)

|

|

|

|

|

|

|

|

Ct2:在t2時之容量值

|

|

|

|

|

端子間

|

﹢350~

|

﹣800~

|

|

Ct1:在t1時之容量值

|

|

|

|

|

端子、封裝間

|

﹣1000

|

﹣5800

|

|

t2:85℃±3℃

|

|

|

|

|

|

ppm∕℃

|

ppm∕℃

|

|

t1:20℃±2℃

|

|

|

|

|

|

|

|

9~2

|

溫度階段

|

|

|

|

|

|

|

|

|

|

1、20±2℃→2、﹣25±2℃

|

|

|

|

使用溫度特性(CKS):

|

|

|

→3、20±2℃→4、85±2℃

|

|

|

|

範圍內之靜電容量變化率:

|

|

→5、20±2℃

|

|

|

|

|

特性B 變化率 ±10%以內

|

9~3

|

容量變化率:(CKS)

|

|

|

|

|

|

|

|

|

C .C(%)=(Ctx-Ct20)/Ct20*100

|

|

|

|

特性E 變化率 +22% -56%以內

|

|

Ctx:溫度階段1、3、5除外,2

|

|

|

|

|

|

|

到4之間任何溫度時之容量

|

|

|

|

特性F 變化率 +30% -80%以內

|

|

值。

|

|

|

|

|

|

|

|

|

|

Ct20:溫度階段3時之容量值。

|

|

10

|

端子強度

|

抗拉強度

|

導線不斷裂

|

,電容器不

|

10~1

|

線徑(mm)

|

負荷重kgs

|

時間(秒)

|

|

|

|

|

破損

|

|

|

0.5Φ

|

0.5

|

10

|

|

|

|

|

|

|

|

0.6Φ~0.8Φ

|

1

|

10

|

|

|

|

|

|

|

10~2

|

製品固定,負荷施力方向為端子引

|

|

|

|

|

|

|

|

出之方向。

|

|

|

|

|

|

彎曲強度

|

導線不致被折斷,電容

|

10~3

|

線徑(mm)

|

負荷重kgs

|

彎曲角度為

|

|

|

|

|

器不破損。

|

|

|

0.5Φ

|

0.25

|

90° 兩回以

|

|

|

|

|

|

|

|

0.6Φ~0.8Φ

|

0.5

|

上。

|

|

11

|

耐振性

|

外觀

|

無顯著之異常

|

|

|

|

|

|

|

|

容量變化

|

在規格範圍內

|

11~1

|

振動頻率10→55→10HZ一分鐘內完

|

|

|

|

Q或散逸

|

在初期規格內

|

|

全成覆振動全振幅1.5mm. 。

|

|

|

|

因數

|

|

|

|

|

|

|

|

|

焊

|

外觀

|

無顯著異常

|

|

12~1

|

焊錫溫度350±10℃

|

|

|

|

|

耐電壓(I) (端子間)

|

合於編號3之性能

|

|

12~2

|

浸漬時間3.5±0.5秒

|

|

|

|

錫

|

|

CCS:

|

|

|

|

|

|

|

|

|

|

特性SL ±2.5%以內

|

|

|

|

|

|

|

12

|

耐

|

|

特性YN ±10%以內

|

|

|

|

|

|

|

|

|

靜電容量

|

CKS:

|

|

12~3

|

在常溫常濕中放置4~24小時後

|

|

|

熱

|

變化率

|

特性B ±10%以內

|

|

|

測定之。

|

|

|

|

|

|

|

特性E ±15%以內

|

|

|

|

|

|

|

|

性

|

|

特性F ±20%以內

|

|

|

|

|

|

|

|

編 號

|

項 目

|

性 能

|

試 驗 方 法

|

|

9

|

靜電容量

|

溫度係數(CCS ):

|

|

9~1

|

溫度係數:(CCS)

|

|

|

|

|

溫 特性

|

SL

|

YN

|

|

PPM/℃=Ct2- Ct1

|

|

|

|

度範圍

|

|

|

|

/Ct1*(t2-t1)

|

|

|

|

|

|

|

|

Ct2:在t2時之容量值

|

|

|

|

|

端子間

|

﹢350~

|

﹣800~

|

|

Ct1:在t1時之容量值

|

|

|

|

|

端子、封裝間

|

﹣1000

|

﹣5800

|

|

t2:85℃±3℃

|

|

|

|

|

|

ppm∕℃

|

ppm∕℃

|

|

t1:20℃±2℃

|

|

|

|

|

|

|

|

9~2

|

溫度階段

|

|

|

|

|

|

|

|

|

|

1、20±2℃→2、﹣25±2℃

|

|

|

|

使用溫度特性(CKS):

|

|

|

→3、20±2℃→4、85±2℃

|

|

|

|

範圍內之靜電容量變化率:

|

|

→5、20±2℃

|

|

|

|

|

特性B 變化率 ±10%以內

|

9~3

|

容量變化率:(CKS)

|

|

|

|

|

|

|

|

|

C .C(%)=(Ctx-Ct20)/Ct20*100

|

|

|

|

特性E 變化率 +22% -56%以內

|

|

Ctx:溫度階段1、3、5除外,2

|

|

|

|

|

|

|

到4之間任何溫度時之容量

|

|

|

|

特性F 變化率 +30% -80%以內

|

|

值。

|

|

|

|

|

|

|

|

|

|

Ct20:溫度階段3時之容量值。

|

|

10

|

端子強度

|

抗拉強度

|

導線不斷裂

|

,電容器不

|

10~1

|

線徑(mm)

|

負荷重kgs

|

時間(秒)

|

|

|

|

|

破損

|

|

|

0.5Φ

|

0.5

|

10

|

|

|

|

|

|

|

|

0.6Φ~0.8Φ

|

1

|

10

|

|

|

|

<

| |